Shop

10 ft Low Proximity Exhaust Hood

3650ELPX-2 – 10ft 0″ Long Low Proximity Sloped Backshelf Hood with Quarter End Panels (shipped loose) and a Built-In 3″ Back Standoff. 14 inch Tall Front

EconAir’s ELPX exhaust hood is a low proximity wall canopy that operates at low CFMs. The product requires minimal kitchen space.

Warning: sizeof(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/woocommerce/single-product/meta.php on line 15

SKU: N/A. Category: Restaurant Hoods.

SAFE & SECURE

Shop With Confidence

Get the lowest prices on filters and kitchen ventilation products with our 150% Lowest Price Guarantee.

-

Description

- 430 SS Where Exposed (1)

- FILTER – 16″ tall x 16″ wide Kleen-Gard Stainless Steel Baffle Filter with Handles and Bottom Hanging Hook, UL Classified (7)

- L55 Series E26 Canopy Light Fixture – High Temp Assembly, Includes Clear Thermal and Shock Resistant Globe (L55 Fixture), Bulbs By Others (3)

- EXHAUST RISER – Factory installed 16″ Diameter X 4″ Height (1)

- 1/2 Pint Grease Cup New Style, Flanged Slotted (2)

- RIGHT QUARTER END PANEL 26″ Top Width, 0″ Bottom Width, 26″ High 430 SS (1)

- LEFT QUARTER END PANEL 26″ Top Width, 0″ Bottom Width, 26″ High 430 SS (1)

Features at a Glance

• ETL Listed and ETL Sanitation Listed Product

• Compact Design

• Superior Exhaust Flow Rates

• Exceptional Capture and Containment of Cooking Vapors

• Wall Configuration

• Stainless Steel Construction

• Double Wall, Insulated Front

• Heavy Duty Grease Baffle Filters (12” high)

• Grease Drain System

• Pre-punched Hanging Angles

• Factory Pre-wired Lighting

• Integral Stainless Steel Double End PanelsOptional Equipment

• Utility Cabinet

• Fire Suppression System

• Electrical Controls

• Rear Make-Up Air Plenum

• Integral Clearance to Combustibles System

• UL Listed Exhaust Fire Damper

• Enclosure Panels to Ceiling

• Type 304 Stainless Steel Construction

– Exposed Surfaces Only

– 100% Construction

• Filters

– High Velocity Cartridge Filters

– Stainless Steel Baffle Type Filters

– High Efficiency Filters

– Captrate Combo, – Solo Filters

• Lighting

– Incandescant

– Recessed Incandescent

– Recessed Fluorescent

• Roof Top Package

• Separate Exhaust and/or Make-Up Air Fans

• Heated Make-Up Air Units

– Direct Gas Fired Heated Make-Up Air Fans

– Indirect Gas Fired Heated Make-Up Air Units

– Electric Heated Make-Up Air Units

• Face Mounted ControlsPerformance Data

Avg Cooking Surface Temp

(°F) – Cooking SurfaceMin Exhaust CFM/ft Max Suggested Supply CFM/ft

via Optional Supply PlenumRecommended Duct Sizing 450°F

Ovens, Steamers, Kettles, Open-Burner Ranges, Griddles, Fryers150 135 Exhaust –

Based on 1500 FPM700°F

Gas Charbroilers, Electric Charbroilers, Mesquite Grills, Charcoal Charbroilers, Gas Conveyor Charbroilers200 180 Supply –

Based on 800 FPM -

10ft Perforated Supply Plenum 10ft Perforated Supply Plenum (PSP), No Plenum

-

ELPX Specifications

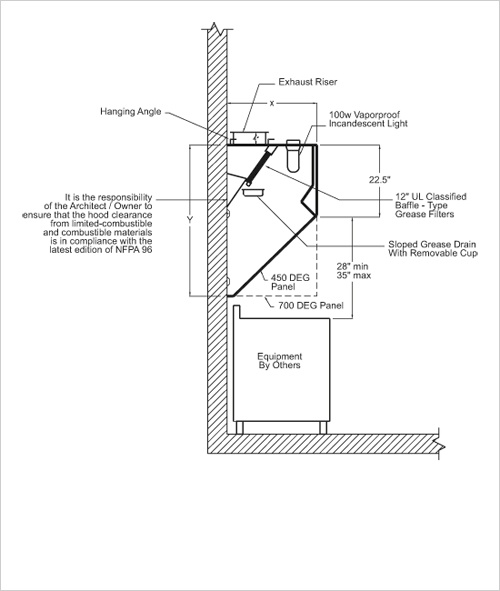

Description The model ELPX is a Type I, wall mounted, exhaust canopy used for collection and removal of grease-laden vapors and smoke over all types of restaurant equipment.

Application The hood shall provide flexibility in designing kitchen ventilation equipment and shall be tested and listed for use over 450°F light/medium duty cooking surfaces and up to 700°F extra heavy duty cooking surfaces.

Construction The hood shall be constructed of type 430 stainless steel with #3 or #4 polish where exposed. All seams shall be welded or in conformance with UL 710 standards. Unexposed surfaces shall be constructed of aluminized steel. Individual component construction shall be determined by manufacturer and ETL. Construction shall be dependent on the structural application to minimize distortion and other defects. All seams, joints and penetrations of the hood where grease-laden vapors and exhaust gases are present must be liquid-tight, continuous welds in accordance with NFPA 96.

The hood shall be constructed to include:

• A double wall insulated front to eliminate condensation and increase rigidity. The insulation shall have a flexural modulus of 475 EI, meet UL 181 requirements and be in accordance with NFPA 90A and 90B.• An integral front baffle to direct grease laden vapors toward the exhaust filter bank.

• An integral grease drain system on the hood back with a minimum 1/8” per foot slope, to include an exposed, removable 1/2 pint grease cup to facilitate cleaning.

• A built-in wiring chase for electrical controls on the front face of the hood designed to avoid penetration of the capture area and eliminate the need for an external chaseway.

• UL incandescent light fixtures and globes, allowing up to a 100 watt standard light bulb, installed and pre-wired to a junction box and installed with a maximum of 3’-6” spacing on center.

• Exhaust duct collar 4” high with 1” flange.

• A minimum of four connections for hanger rods. Connectors shall have 9/16” holes pre-punched in 1 1/2” x 1 1/2” angle iron at the factory to allow for hanger rod connection by others.

• UL Classified aluminum baffle filters, with size and quantity determined by the hood’s dimensional parameters, but extending the full length of the hood with filler panels not to exceed 6”.Certifications The hood shall be ETL Listed, comply with UL 710 Standards and shall be built in accordance with NFPA96. Hood shall be tested for compliance with the ETL Sanitation Mark.

Documentation Manufacturer shall furnish complete computer generated submittal drawings including hood section view(s), plan view(s), duct sizing, and CFM and static pressure requirements. Static pressure, air velocity and air volume requirements indicated on drawings shall be precise and accurate and hood shall perform to said specifications. Drawings shall be available to the engineer, architect and owner for their use in construction, operation and maintenance.

-

Sectional View

-

Only logged in customers who have purchased this product may leave a review.

Related Products

Cart

- No products in the cart.

There are no reviews yet.